Cutting Edge Crossover Solutions

In the oil and gas industry, crossovers are essential connectors that allow different types of equipment to work together in a wellbore. Cutting of crossovers refers to the precise and controlled process of removing or disconnecting these connections during well operations. This technique is often required during well interventions, repairs, and maintenance to ensure the seamless operation of the well. Our cutting services are designed to provide safe, efficient, and precise cutting of crossovers to allow for easy equipment removal or replacement, optimize well performance, and minimize downtime.

Our Crossover Cutting Services

Precision Cutting

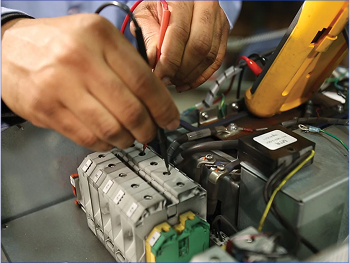

We utilize state-of-the-art cutting equipment, including hydraulic cutters and specialized saws, to ensure that the cutting process is performed with precision and without damaging surrounding equipment. Our cutting techniques are suitable for all sizes of crossovers, including those made from tough, high-strength alloys.

Safe and Controlled Operations

Our team follows strict safety protocols during the cutting process to ensure that operations are performed safely without risk to personnel, equipment, or the environment. Our experts are trained to handle high-pressure systems, live well conditions, and challenging environments.

Wellbore Integrity Protection

We understand the importance of wellbore protection. Our cutting procedures are designed to maintain the integrity of the wellbore, ensuring that no debris or damage is caused during the cutting process. We take extra precautions to prevent any issues that could affect the long-term stability of the well.

Custom Solutions for Every Job

We know that each well has unique challenges. Our crossover cutting service is tailored to your specific needs. Whether you require a simple cut or a more complex solution, we collaborate closely with you to develop the most effective cutting plan for your well conditions and operational requirements.

Cutting for Equipment Retrieval or Replacement

When equipment is stuck or damaged in the well, traditional methods may not be sufficient. Our cutting services provide an effective solution for retrieving or replacing equipment, allowing you to maintain well performance without causing further damage. We work quickly and efficiently to free trapped tools or facilitate the replacement of outdated equipment.

Post-Cutting Inspection and Evaluation

After cutting the crossover, we conduct thorough post-cutting inspections. Our team ensures that the cut is clean, precise, and effective, and we provide you with a detailed report on the condition of the wellbore and any equipment involved. This inspection ensures that the well is ready for continued operation and highlights any further maintenance or optimization needs.

Optimize Your Well Performance with CerTech Energy

Partner with us for safe, efficient, and cost-effective slickline and well intervention services.